Rigorous Quality Control for Superior PRO-MIX Value-Added Growing Media

PRO-MIX has established itself as a leading brand in growing media products, proud of more than 50 years of existence. Known for its consistency and overall product quality, the Premier Tech brand has innovated since its inception with cutting-edge products that are adapted to growers' needs. Today, PRO-MIX continues to be the reference for growing media with much of the recognition attributed to the active ingredients incorporated in the products. Active ingredients provide a beneficial component that is not available in any other growing media on the market.

PRO-MIX value-added growing media include two different active ingredients, developed and produced by Premier Tech:

- AGTIV® REACH™ (Glomus intraradices, PTB297 Technology)

- AGTIV® DEFEND™ (Bacillus pumilus, PTB180 Technology)

- AGTIV® FORTIFY™ (a mix of PTB297 and PTB180 technologies)

Premier Tech produces “inoculants” (or “inoculums”), which are active ingredients that are formulated in a liquid suspension for incorporation into growing media via proprietary processes, or as “stand-alone” inoculants, formulated with carrier material in powder or granules. PRO-MIX CONNECT is an example of a “stand-alone” mycorrhizal inoculant.

Premier Tech has proven to be a world leader in the production of aseptic mycorrhizal inoculum and has since developed other inoculums with the same care and quest for excellence. But it takes more than good strains and well-adapted formulations to stand out in the industry. A premium quality control process, for inoculums and value-added growing media, is key to achieving the results and reputation of PRO-MIX.

“One of the most promising ways to increase biofertilizer [inoculant] efficacy is to introduce robust quality control systems.1”

Discover how Premier Tech masters all the steps for the production of its reliable mycorrhizal and Bacillus inoculants and their formulation in finished products.

Quality Control of World-Leading Mycorrhizal Inoculant

With products that guarantee a high concentration of viable spores, leading to an efficient colonization of plants, Premier Tech has made its mark since the inauguration of its mycorrhizal inoculum production facility in 2000.

“We control the quality from the biofermenters to the formulated products”, says Régine Otis, IR&D Coordinator, and every aspect of the end products’ viability and efficacy is verified for each produced batch.

Mycorrhizal fungi (PTB297 Technology) are produced at an industrial scale in a completely aseptic production facility in La Pocatière, Québec, Canada. Recognized as the first company worldwide to produce spores in vitro in a mycoreactor, a rigorous quality control process has been developed to ensure the viability and efficacy of the products.

- Produced spores in liquid suspension are tested for concentration and viability. The spores need to be whole with their structure intact, and filled with lipids to be able to colonize plants. Unlike most inoculant producers on the market, only viable spores are counted. We do not include hyphae fragments or non-viable spores, which are ruptured, deformed or not filled with lipids.

Learn more about Premier Tech’s expertise in biological active ingredients.

Premier Tech’s mycorrhizal fungi production facilities hold strict aseptic processes. Source: Premier Tech - The inoculum is formulated within growing media, or on a powder carrier for PRO-MIX CONNECT, and is once again tested for concentration and viability, with special proprietary methods. As production and formulation cause stress to the microorganisms, this step is crucial to ensure product integrity.

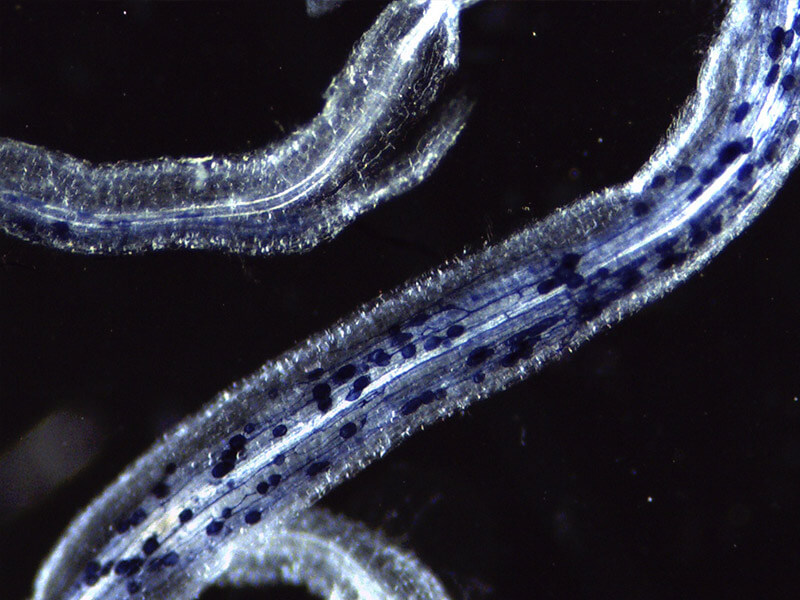

- Product samples are used to grow plants in Premier Tech’s labs and greenhouses. Plants are harvested after a few weeks to verify the colonization rate and efficacy of the product. This verification is done by washing the roots, staining them to finally observing them with a microscope.

The presence of mycorrhizal structures (arbuscules and vesicles) inside the roots, and the intensity of their presence (colonization rate) indicate the active ingredient is viable. In other words, intraradical colonization, i.e. inside the roots, means that the fungi can develop an extraradical network in the soil and help plants through symbiosis.

Quality Control of Bacillus pumilus

Bacillus bacteria (PTB180 Technology) are produced in biofermenters in another aseptic facility in La Pocatière, and the concentrated inoculum is in liquid form. This inoculum’s quality control process has been developed with the same rigor as mycorrhizal fungi, to ensure optimal efficacy.

- Concentrated production is tested by calculating the cfu/ml or cfu/g (cfu: colony forming units, i.e. active cells of bacteria).

- Concentrated inoculum is incorporated to formulated growing media according to guaranteed concentrations.

Premier Tech biofermenters in La Pocatière, Qc. Source: Premier Tech - Every batch of growing medium is tested for concentration of cfu/ml or cfu/g. Special methods have been developed to test concentration on any growing medium, or stand-alone inoculants.

- Product samples from every production facility are used to grow plants in Premier Tech’s labs and greenhouses, to test the active ingredient’s efficacy. Plants are then harvested and verified to assess the active ingredient’s efficacy.

PRO-MIX products, whether they contain one or both active ingredients, are all tested the same way to ensure that mycorrhizae and Bacillus, known for their great compatibility, colonize plants together as expected. Learn more about their tripartite association by reading Get More Value From The Tripartite Association.

The whole process aims to provide a ready-to-use product for growers, with proven reliability and performance.

Delivering to Expectations

“My goal as a Quality Manager is to maintain product consistency, because that is what our clients expect, and that’s what PRO-MIX stands for. Our value-added products respect the same quality standards, batch after batch.” - Frédéric Simard, Quality Manager for Premier Tech

What good comes out of a controlled, contaminant-free and consistent product, selected and developed by experts? Our Efficacy Reports gather data about new and existing products, and the results show that Premier Tech value-added growing media and inoculants deliver higher yields and plant quality than regular products.

Seeing the quality control process as a whole is key to generating success, from Premier Tech’s fermenters to full-grown crops.

40 Years of Expertise

40 years after setting up a research facility on biological active ingredients, Premier Tech has increased efforts into creating value for growers, with premium quality products that increase crop yields and plant health.

It’s the constant dedication and pride that Premier Tech team members take in presenting the best possible product to the market that sets the standards for the future of crop production.

1. Lesueur et al. 2016, The production and potential of biofertilizers to improve crop yields. In Arora et al. Bioformulations: for sustainable agriculture, Springer, Berlin, Germany, pp.71-92.